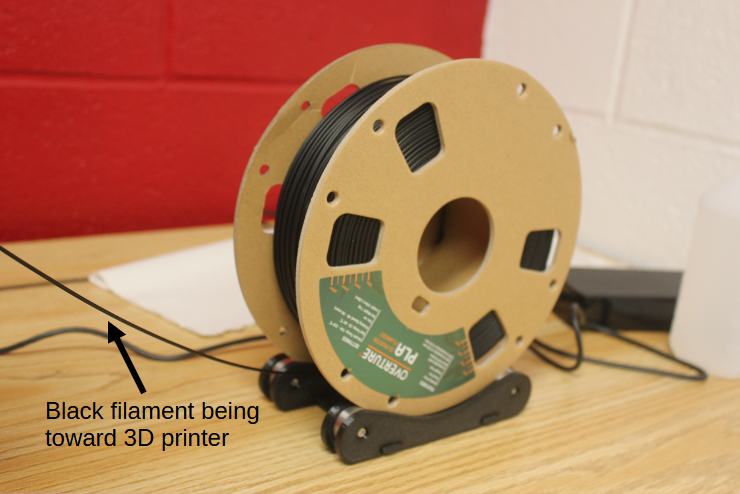

Filament Wheel and Filament

The plastic that is melted and pushed out the nozzle of the 3D printer is called Filament and wrapped around the Filament Wheel, shown in the next picture.

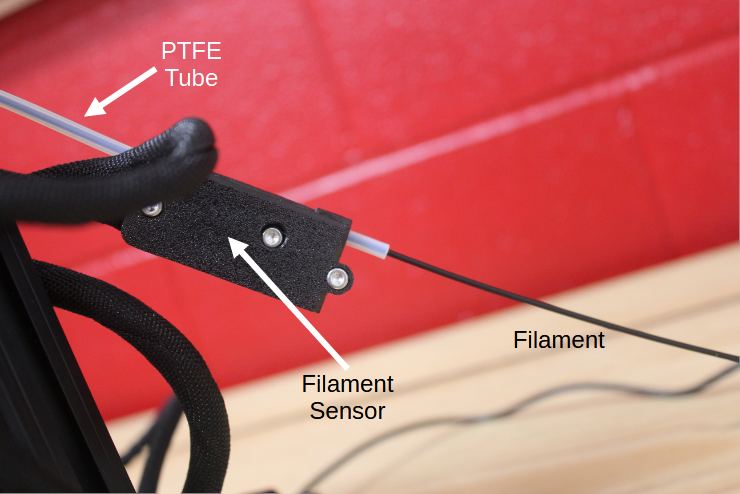

As the filament is pulled towards the 3D printer, the wheel rotates on rollers as the filament unwinds from the wheel. After being pulled from the wheel, the filament enters a Filament Sensor that tells the 3D printer that the filament is loaded. The sensor is shown below.

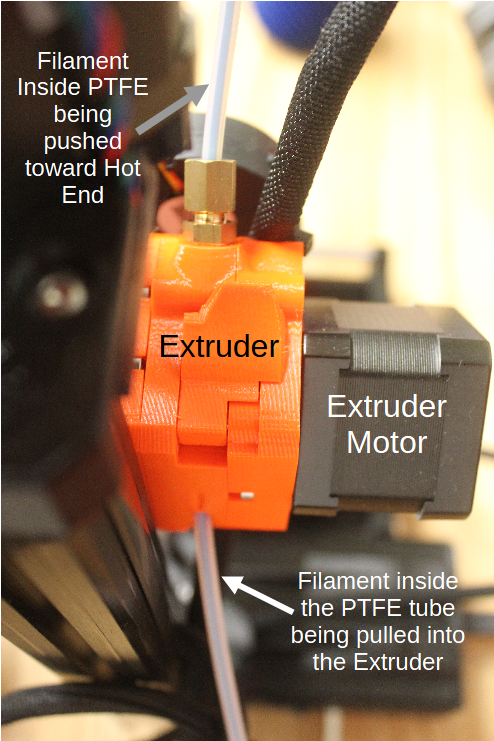

Before the filament enters the sensor, it goes into a white plastic tube made of a special smooth plastic called PTFE. The PTFE Tube helps guide the filament smoothly so that it doesn’t get stuck on anything. After the filament leaves the sensor, it gets pulled into the Extruder, shown in the next picture.

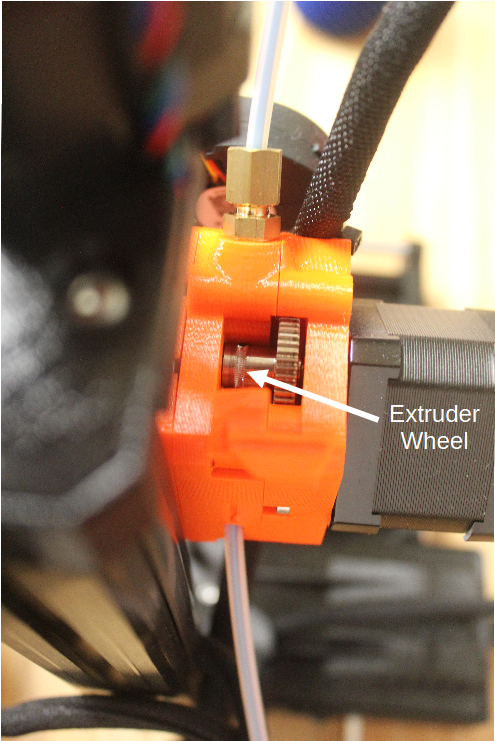

The Extruder is actually just a wheel with “teeth” that grab the filament. The wheel is connected to an Extruder Motor that causes it to rotate. As the wheel rotates, the teeth in the wheel pulls/pushes the filament along through the Extruder. In the next picture, the orange plastic cover has been removed so you can see the Extruder Wheel. The arrow is pointing directly at the rough grooves that have been stamped into the metal. These grooves are the teeth that grab the filament and pull it along from its starting point at the filament wheel.

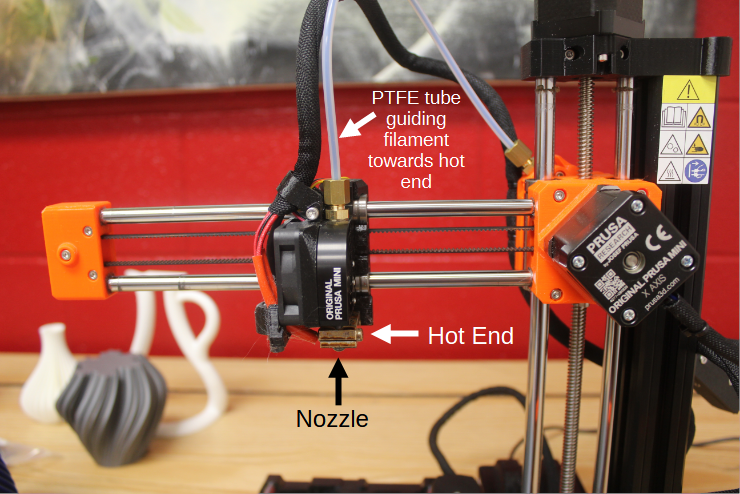

As the next picture shows, the filament now enters the part of the 3D printer where the Hot End is located. In the Hot End, the plastic filament is heated to a high temperature. The plastic melts, and is eventually pushed out the nozzle. In the next two pictures, you can see the PTFE tube that guides the filament into the printer head towards the Hot End and the Nozzle.

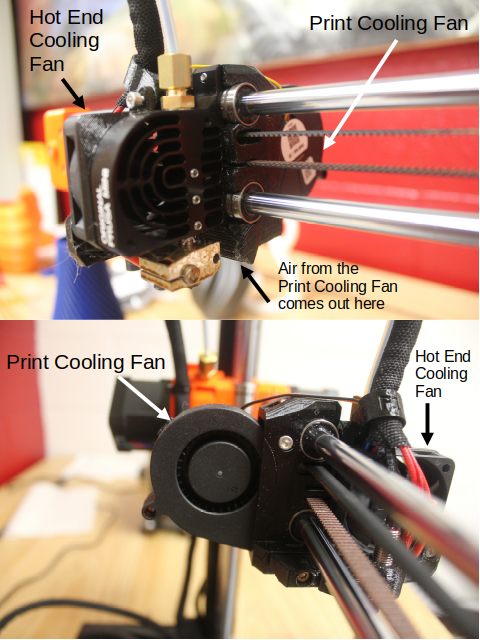

Notice that the Hot End and a bunch of black plastic parts and some wires are all attached to two metal rods that are part of the “arm” sticking out over the Heat Bed and Metal Plate. In the next two pictures (taken on different sides of the arm) you can see that the black plastic parts are actually two fans attached to the Hot End. One is the Print Cooling Fan and the other is the Hot End Cooling Fan.

The Print Cooling Fan blows air directly onto the object being printed on the metal plate so that the melted plastic cools a little and stays in place properly in the object after it is extruded. The Print Cooling Fan blades can’t be seen since they are sealed inside the black fan covering. The Hot End Cooling fan keeps the Hot End from getting too hot.